Jambette's production process

By Claudia Carrier | Read time 1 minute | Published on

Categories: Enterprise

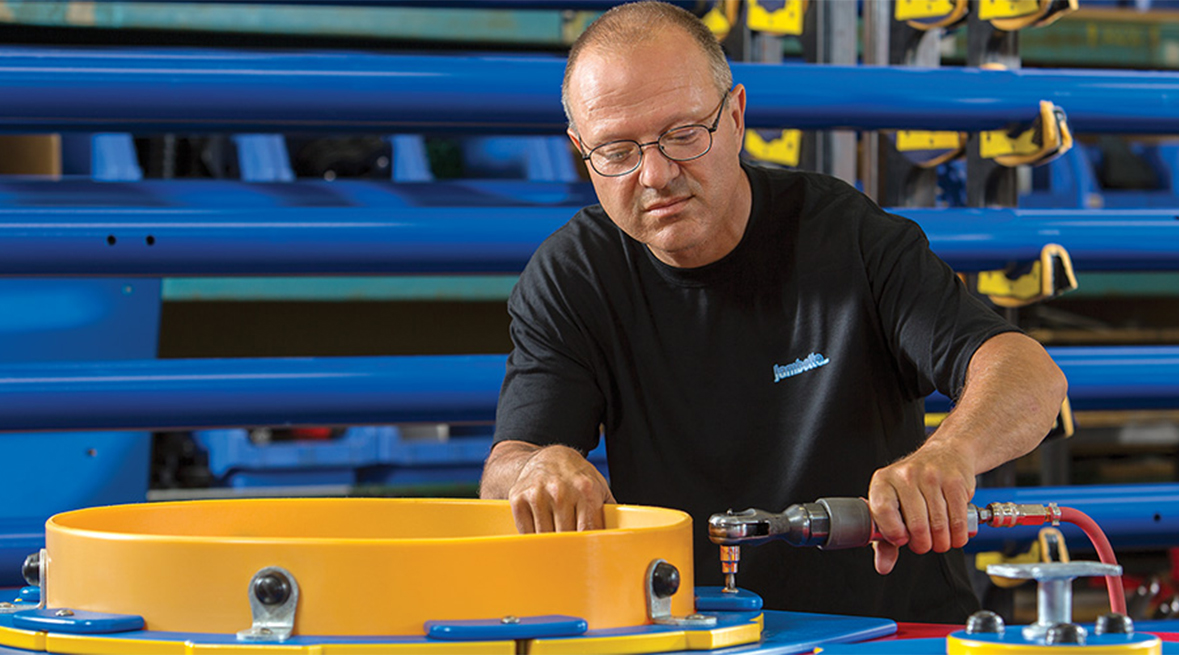

Jambette produces recreational equipment with precision, using a process that has been carefully fine-tuned over the years. Nearly 90% of all our materials are sourced in Canada and we use aluminium more than anyone else on the market. We exude quality from every angle: industry-renowned paint finish, welds produced with exceptional care and high-quality packaging.

But what is the production process that allows us to reach these high quality standards?

ALUMINIUM-STEEL

1 Cutting

2 Forming

3 Assembly

4 Surface preparation

5 Painting

PANELS

1 Cutting

2 Finishing

MOULDED COMPONENTS

1 Preparation

2 Finishing

SPECIAL COATINGS

1 Dipping and fusion

FINAL STEPS

1 Preassembly

2 Packaging

3 Delivery

4 Installation

______________________________

Curious to learn how Jambette has evolved to become the company it is today?

Discover Jambette's DNA HERE!